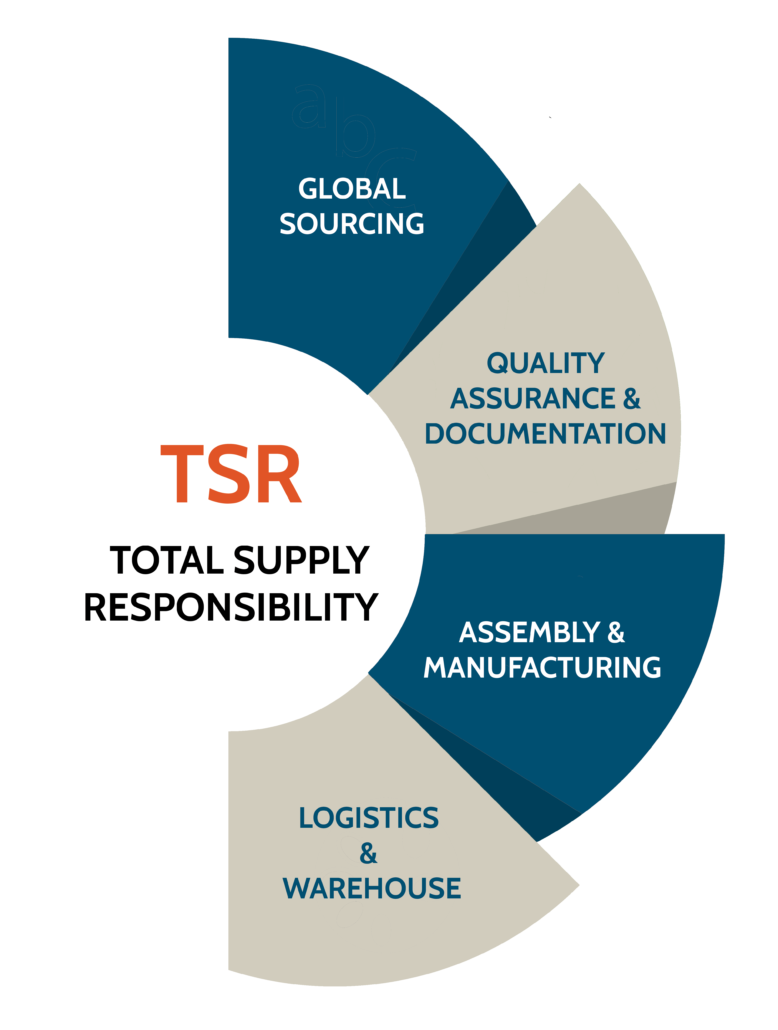

Even if we supply thousands of standard products, our major strength is customized designed products and solutions, as well as global sourcing, Total Supply Responsibility (TSR), where we in tight cooperation with our customers and manufacturers “bring ideas to serial production”. The goal for our TSR concept is to allow customers to optimize their KPI’s through supplier reductions, cost optimization and consolidation.

We all face many different challenges such as increased demand for supplier performance, quality control, global access, sourcing, stock keeping and administration. We offer an alternative of supply chain services such as sourcing, assembly and qualification to our customers and supplier.

Through a Total Supply Responsibility (TSR) for the supply chain governed by written and agreed delivery terms, TSR also includes deliveries within the prescribed metrics regarding delivery precision and quality requirements and responsibility for the product.

Through active processing, monitoring and follow-up of all stages of the support chain, we secure your supply chain.

Handling this type of business, we can help our customers with their logistics, quality and warehousing. These companies perhaps need someone to handle logistics, quality and warehousing of parts from Europe to Asia, USA to Europe, Asia and vice versa. They also need sourcing and domestic development of future suppliers, as well as possible assembly.